Excellence in...

UNMANNED INSPECTION SERVICES

-

AIR

Unmanned Aerial Systems (UAS) inspect

hard-to-reach at-height assets -

LAND

Surface robotics allow for hazardous area and confined space inspections

-

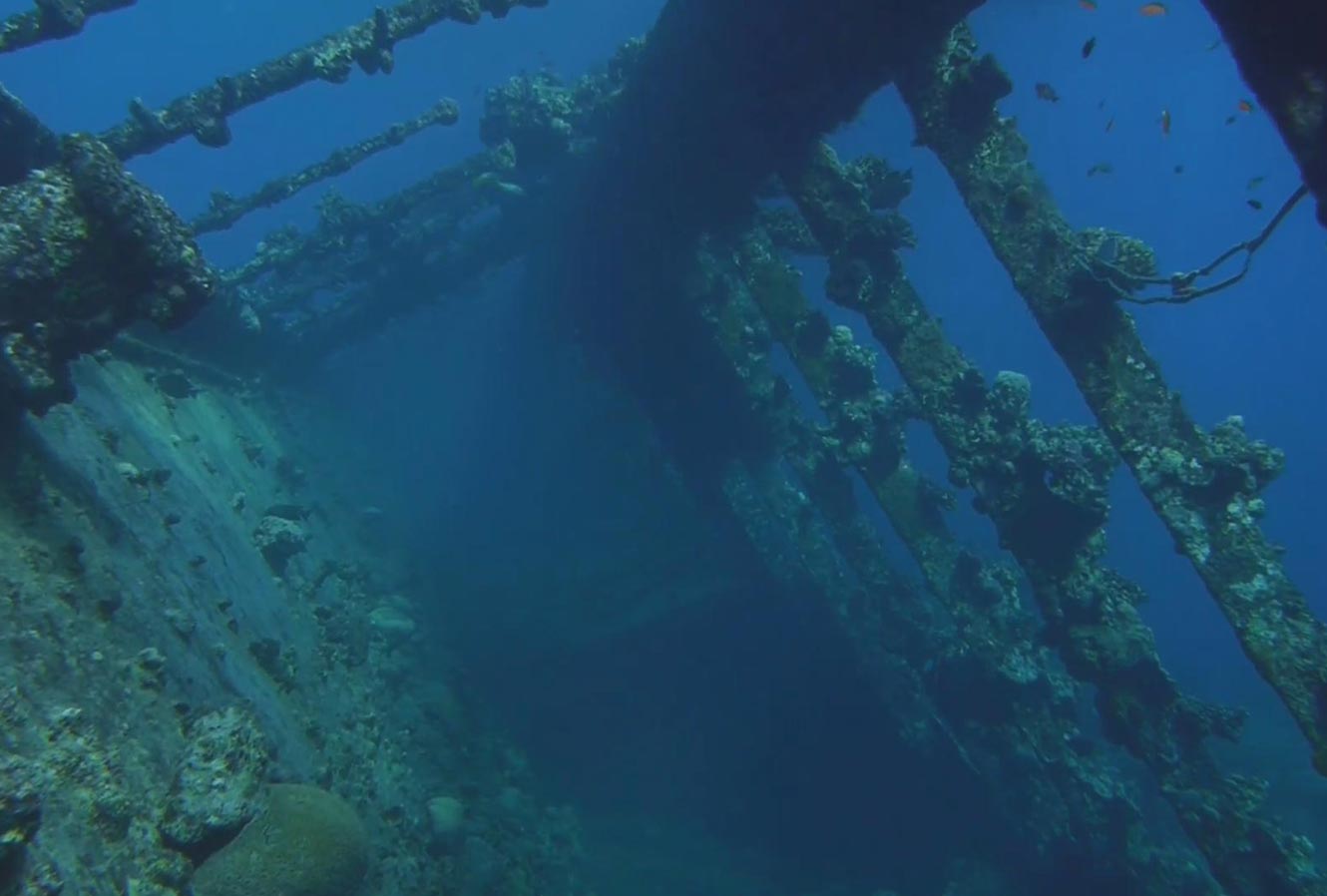

SEA

Remote Underwater Vehicles (ROVs) provide real-time video and data from confined underwater locations

AETOS, a member company of MISTRAS Group, Inc., is an industry pioneer in utilizing aerial, surface, and submersible robotic technologies to provide non-destructive testing (NDT) inspections for the oil & gas, petrochemical, civil infrastructure, energy, and utility industries. AETOS has revolutionized maintenance and inspection processes to reduce downtime and costs, making them safer and more efficient, all while working diligently to integrate the best platform and payload technologies to meet demanding industry needs.

AETOS’ NDT drone inspection capabilities, in tandem with MISTRAS’ offerings as a one source global provider of asset protection solutions, offer the opportunity for fully-integrated asset management, even in confined or hazardous locations. Our combined technology-enabled solutions provide facility operators with uniquely beneficial solutions to perform in-service inspections, improve operational health, manage and identify flaws, support crises and catastrophes, oversee construction and repair work, and cost-effectively monitor indoor and outdoor assets.

UNMANNED AIR SERVICES

AETOS comes equipped with a team of licensed pilots with advanced drone inspection experience to offer safe, informed, and efficient aerial NDT inspections, mapping, and surveying. We were the first company to receive FAA approval to fly Unmanned Aerial Systems (UAS)–also known as Unmanned Aerial Vehicles (UAV)–in the petrochemical industry. We have since extended our UAS/UAV drone inspection and flying experience into civil and energy infrastructure, utilities, and environmental industry inspections. Our UAS are proven to be the safest, most capable and robust aircraft available for aerial NDT inspections, allowing them to acquire accurate data and high-resolution imagery of bridges, buildings, tanks, live flare stacks, and other energy and general industrial infrastructure.

As professional pilots, we place our focus on collecting the most reliable data for enhanced inspections and mapping, and we do this by maintaining developmental relationships with drone manufacturers to consistently provide industry-best solutions. Our drones are capable of being equipped with many types of payloads for a variety of inspection needs, including:

- High resolution video/still cameras

- Infrared imagers and gas detection

- Multispectral and hyperspectral cameras

- UV imagers

- Environmental sensors and more

Limits cost and safety hazards associated with at-height work

Rapid mobilization and reduced inspection time

Lowers downtime and allows assets to stay in service during inspections

UNMANNED LAND SERVICES

AETOS has partners in the robotic industry to engineer custom solutions providing the best fit for your need, no matter the transportation, oil and gas, petrochemical, or process industry inspection application. Our manufacturing partnerships enable our surface drones to envelop an extensive range of robot and crawler designs, adaptable to many different industrial inspection demands. This technology ranges from very large to pint-sized, wired and wireless, and wall climbers and pipe crawlers, all with varying levels of automation capability.

The unmanned drones are equipped with non-destructive testing (NDT) tools for a wide range of robotic asset inspections, including tanks, vessels, and more. AETOS is working closely with Level III inspectors and robotic technology manufacturers to expand remote visual inspection and NDT capabilities. We have noticed a gap between the industry’s desire to keep people out of confined and hazardous areas, and the personnel to operate the robotic technology that can close it. Our team intends to realize that closure.

Adaptable designs for different unmanned inspection needs

Capable of accessing difficult or unreachable locations

Keep your product flowing with in-service inspections

UNMANNED SEA SERVICES

Use of robotic NDT inspections eliminates the need to deploy manned watercraft or engage divers in hazardous confined spaces, reduces pre-inspection preparation, and adds efficiency that reduces overall cost and risk. AETOS’ unmanned infrastructure, oil & gas, and maritime industry robotic inspections use submersible ROVs fitted with non-destructive testing (NDT) tools to provide real-time feedback, streaming video, and sensor data.

Our ROVs are configured for conducting various liquid-based robotic NDT inspections of maritime areas, sub-sea canals, dams, bridges, sunken structures, and piping/pipelines. Our systems can be equipped with a variety of NDT sensors, sonar, lighting, and manipulator arms designed to meet the needs of specific sub-sea inspection applications.

Eliminates the need for manned watercrafts

Real-time, quality imaging and video streaming

Reduced pre-inspection preparation

Confined Space Entry

One of AETOS’ priorities is to reduce the need for confined space entry (CSE). This type of work is dangerous and involves a great deal of preparation, additional equipment, and personnel to carry out. Risks are further enhanced when CSE inspections are needed in elevated areas, requiring expensive and time-consuming scaffolding to be constructed. In these cases, unmanned NDT inspections are a valuable alternative.

AETOS takes on challenging CSE inspections in a variety of industries, including the energy, petrochemical, municipal, and infrastructure sectors. Already, we’re capable of completing visual, ultrasonic, infrared, and eddy current CSE inspections, and we are working with industry leaders to further develop additional applications. We are constantly evolving our indoor aerial capabilities in addition to adding other important techniques to our toolbox, like 360-degree virtual reality cameras and robotic crawlers.

ENERGY

- Boilers and HRSGs

- Stacks

- Nuclear Power Plants (to eliminate human exposure)

PETROCHEMICAL

MANUFACTURING

FACILITIES

- Boilers and HRSGs

- Piping

- Columns

- Tanks

- Pressure Vessels

MUNICIPALITES

- Storage Tanks

- Water Towers

- Piping

- Sewers

OTHER INDUSTRIES

- Cargo Ship Holds

- Ballast Tanks

- Abandoned/Unsafe Structures

ABOUT AETOS

FAQ

Are unmanned aerial systems (Drones, UAV, sUAS) legal for commercial use?

In 2016, The FAA and Department of Transportation (DOT) released federal regulations regarding the use of unmanned drones, endorsing their use in commercial applications. Prior to this publication, AETOS had received an FAA 333 Exemption, allowing us to fly unmanned aerial systems in the national airspace.

You don’t have a location near me, can you still help us?

Absolutely! We are expanding rapidly with plans for multiple regional locations. In the meantime we will travel to any site in the country for a personal demonstration of our unmanned drones.

I have an application and cannot find a robotic solution, can you build it?

While we are not manufacturers of robotic unmanned aerial systems, we work diligently with industry leaders to develop appropriate solutions. In some cases, we can integrate systems and modify as needed to fit our clients’ needs. In other cases, we will engage our manufacturing partners and enter into development for new capabilities.

How long does it take to conduct unmanned robotic inspections?

This varies greatly with the area to be inspected and the type of NDT inspection that needs to be conducted.

In some cases robots can be faster than human inspection, but in general, robots are slower at completing the inspection task itself. However, factoring the time it takes to prepare, mobilize, and permit a confined space entry (CSE), robots will be faster. This means less down time.

Finally, while being faster considering total scope, robots are safer. Eliminating CSE is a major reason to use unmanned drones.

Can unmanned drones be hijacked?

Simply, no. All wireless vehicles are operated using an encrypted communications link.

Is data gathered during inspections secure?

Yes. For wireless vehicles with real-time data streaming, all datalinks are encrypted. For wired or tethered vehicles, all information travels over a physical cable.

Since companies view their NDT inspection data as sensitive, unless the client has requested reports, we will give the data storage medium to a company representative to limit access.

How do you manage operations in hazardous (classified) areas?

Through the FMEA process, we determine with clients the extent to which unmanned operations in classified areas will take place.

With current clients, our aerial inspection platforms have been approved over Class I Division I and through (no loitering) Class I Division II areas. With camera and sensor technology today, we can comply with these classification guidelines and still conduct an effective NDT inspection.

Are unmanned drones intrinsically safe?

No. However, we are exploring classification with manufacturers of unmanned drones. All robotic systems we have used to date use brushless motors which are magnetic and create no spark. They also utilize water tight electronic compartments.

Why don’t you have any photos of your work on the website?

As much as we’d like to show you all of the great things we’re doing, the NDT information we gather at client facilities is confidential and we cannot share it. We hope to get a few photos and promotional videos released in the future.

Given the regulations, how much aerial inspection experience does AETOS have?

AETOS was the first company to receive FAA approval to fly UAS in the petrochemical industry, beginning in 2012. Though the industry is new, AETOS has as much or more experience than any other company currently operating in this line of work.

Starting in 2012, AETOS facilitated an aeronautical research, inspection application, and operational safety project under a Certificate of Authorization (COA) held by Northwestern Michigan College and The Dow Chemical Company. Through this project, we defined safe operating procedures and checklists for manufacturing facilities, determined high value applications, and developed operating techniques to maximize NDT data acquisition.

How do you manage operations in hazardous (classified) areas?

Through the FMEA process, we determine with clients the extent to which unmanned operations in classified areas will take place.

With current clients, our aerial inspection platforms have been approved over Class I Division I and through (no loitering) Class I Division II areas. With camera and sensor technology today, we can comply with these classification guidelines and still conduct an effective NDT inspection.

Our other robotic systems are currently operated with clients in unclassified areas with a low-energy hot work permit.

Is data gathered during inspections secure?

Yes. For wireless vehicles with real-time data streaming, all datalinks are encrypted. For wired or tethered vehicles, all information travels over a physical cable.

Since companies view their NDT inspections as sensitive, unless the client has requested reports, we will give the data storage medium to a company representative to limit access.

I have an application and cannot find a robotic solution, can you build it?

While we are not manufacturers of robotic unmanned aerial systems, we work diligently with industry leaders to develop appropriate solutions. In some cases, we can integrate systems and modify as needed to fit our clients’ needs. In other cases, we will engage our manufacturing partners and enter into development for new capabilities.

Are unmanned aerial systems (Drones, UAV, smallUAS [sUAS]) legal for commercial use?

In 2016, The FAA and Department of Transportation (Department of Transportation) released federal regulations regarding the use of unmanned drones, endorsing their use in commercial applications. Prior to this publication, AETOS had received an FAA 333 Exemption, allowing us to fly unmanned aerial systems in the national airspace.

You don’t have a location near me, can you still help us?

Absolutely! We are expanding rapidly with plans for multiple regional locations. In the meantime we will travel to any site in the country for a personal demonstration of our unmanned drones.

Can unmanned drones be hijacked?

Simply, no. All wireless vehicles are operated using an encrypted communications link.

What happens if the UAS loses communications with the Ground Station?

The UAS will climb to an altitude above the highest obstacle, return home, and loiter above the launch location. If communication link is not restored, the UAS will land itself where it launched from.

How long does it take to do an inspection using UAS?

UAS inspection is extremely efficient; an abundance of NDT information can be gathered quickly.

While the complexity of the task needs to be kept in mind, we can do 5-6 thorough, operating flare stack inspections in a single day. Things like distillation columns, tank tops, overhead piping, and cooling towers can be much simpler and take less time, generally.

GIS/mapping projects vary by area. We can cover about 100 acres in a day. Processing time for large mapping projects can take up to one week using specialized, high-powered computers to put the data together.

Are unmanned drones intrinsically safe?

No. However, we are exploring classification with manufacturers of unmanned drones. All robotic systems we have used to date use brushless motors which are magnetic and create no spark. They also utilize water tight electronic compartments.

Why don’t you have any photos of your work on the website?

As much as we’d like to show you all of the great things we’re doing, the NDT information we gather at client facilities is confidential and we cannot share it. We hope to get a few photos and promotional videos released in the future.

Given the regulations, how much aerial inspection experience does AETOS have?

AETOS was the first company to receive FAA approval to fly UAS in the petrochemical industry, beginning in 2012. Though the industry is new, AETOS has as much or more experience than any other company currently operating in this line of work.

Starting in 2012, AETOS facilitated an aeronautical research, inspection application, and operational safety project under a Certificate of Authorization (COA) held by Northwestern Michigan College and The Dow Chemical Company. Through this project, we defined safe operating procedures and checklists for manufacturing facilities, determined high value applications, and developed operating techniques to optimize NDT data acquisition.

You don’t have a location near me, can you still help us?

Absolutely! We are expanding rapidly with plans for multiple regional locations. In the meantime we will travel to any site in the country for a personal demonstration of our unmanned drones.

Why don’t you have any photos of your work on the website?

As much as we’d like to show you all of the great things we’re doing, the NDT information we gather at client facilities is confidential and we cannot share it. We hope to get a few photos and promotional videos released in the future.

How long does it take to conduct unmanned robotic inspections?

This varies greatly with the area to be inspected and the type of NDT inspection that needs to be conducted.

In some cases robots can be faster than human inspection, but in general, robots are slower at completing the inspection task itself. However, factoring the time it takes to prepare, mobilize, and permit a confined space entry (CSE), robots will be faster. This means less down time.

Finally, while being faster considering total scope, robots are safer. Eliminating CSE is a major reason to use unmanned drones.

Is data gathered during inspections secure?

Yes. For wireless vehicles with real-time data streaming, all datalinks are encrypted. For wired or tethered vehicles, all information travels over a physical cable.

Since companies view their NDT inspection data as sensitive, unless the client has requested reports, we will give the data storage medium to a company representative to limit access.

Can unmanned drones be hijacked?

Simply, no. All wireless vehicles are operated using an encrypted communications link.

How do you manage operations in hazardous (classified) areas?

Through the FMEA process, we determine with clients the extent to which unmanned operations in classified areas will take place.

With current clients, our aerial inspection platforms have been approved over Class I Division I and through (no loitering) Class I Division II areas. With camera and sensor technology today, we can comply with these classification guidelines and still conduct an effective NDT inspection.

Our other unmanned drones are currently operated with clients in unclassified areas with a low-energy hot work permit.

Are unmanned drones intrinsically safe?

No. However, we are exploring classification with manufacturers of unmanned drones. All robotic systems we have used to date use brushless motors which are magnetic and create no spark. They also utilize water tight electronic compartments.

I have an application and cannot find a robotic solution, can you build it?

While we are not manufacturers of robotic unmanned aerial systems, we work diligently with industry leaders to develop appropriate solutions. In some cases, we can integrate systems and modify as needed to fit our clients’ needs. In other cases, we will engage our manufacturing partners and enter into development for new capabilities.

You don’t have a location near me, can you still help us?

Absolutely! We are expanding rapidly with plans for multiple regional locations. In the meantime we will travel to any site in the country for a personal demonstration of our unmanned drones.

Are unmanned drones intrinsically safe?

No. However, we are exploring classification with manufacturers of unmanned drones. All robotic systems we have used to date use brushless motors which are magnetic and create no spark. They also utilize water tight electronic compartments.

How long does it take to conduct unmanned robotic inspections?

This varies greatly with the area to be inspected and the type of NDT inspection that needs to be conducted.

In some cases robots can be faster than human inspection, but in general, robots are slower at completing the inspection task itself. However, factoring the time it takes to prepare, blind, and permit a confined space entry (CSE), robots will be faster. This means less down time.

Finally, while being faster considering total scope, robots are safer. Eliminating CSE is a major reason to use unmanned drones.

Why don’t you have any photos of your work on the website?

As much as we’d like to show you all of the great things we’re doing, the NDT information we gather at client facilities is confidential and we cannot share it. We hope to get a few photos and promotional videos released in the future.

Is data gathered during inspections secure?

Yes. For wireless vehicles with real-time data streaming, all datalinks are encrypted. For wired or tethered vehicles, all information travels over a physical cable.

Since companies view their NDT inspection data as sensitive, unless the client has requested reports, we will give the data storage medium to a company representative to limit access.

How do you manage operations in hazardous (classified) areas?

Through the FMEA process, we determine with clients the extent to which unmanned operations in classified areas will take place.

With current clients, our aerial inspection platforms have been approved over Class I Division I and through (no loitering) Class I Division II areas. With camera and sensor technology today, we can comply with these classification guidelines and still conduct an effective NDT inspection.

Our other robotic technologies are currently operated with clients in unclassified areas with a low-energy hot work permit.

I have an application and cannot find a robotic solution, can you build it?

While we are not manufacturers of robotic unmanned aerial systems, we work diligently with industry leaders to develop appropriate solutions. In some cases, we can integrate systems and modify as needed to fit our clients’ needs. In other cases, we will engage our manufacturing partners and enter into development for new capabilities.

Literature

CONTACT AETOS

Your Message has been submitted.

We’d Love to Hear from You, Get In Touch With Us!

We’re sure you have questions. Want a closer look at what we do and some of our equipment? Sign up for our interactive AirTour to see what our drones see. We’d love to visit your site to show you how we can help; we’d be thrilled to talk about your specific needs in person.

Hope to speak with you soon!